The grocery sector has had a turbulent few years, facing rising costs and increasing availability disruption. In this environment the resilience and agility of supply chains remains critical. While embracing these challenges, supply chains must also accelerate their efforts to reduce waste and emissions.

Last year Simply Supply Chain ran initiatives in support of these critical priorities, and we are delighted to see considerable progress and tangible results from our collaborative efforts. We are pleased to share our 2023 highlights and new initiatives for 2024, as we will continue to build momentum.

Last year Simply Supply Chain ran initiatives in support of these critical priorities, and we are delighted to see considerable progress and tangible results from our collaborative efforts. We are pleased to share our 2023 highlights and new initiatives for 2024, as we will continue to build momentum.

Kind regards,

![]()

Jonathan Kittow, Director of Simply Supply Chain

2023 Projects - Operational Effectiveness

Warehouse manning levels, and most recently the increased minimum wage, continue to heap pressure on both chilled and ambient supply chains particularity where case-picking prevails (and where retailer pressure is reducing MOQs, exacerbating the challenge). With logistics costs increasing, despite inflation reducing, performance efficiency and effectiveness remain top of the priority list.

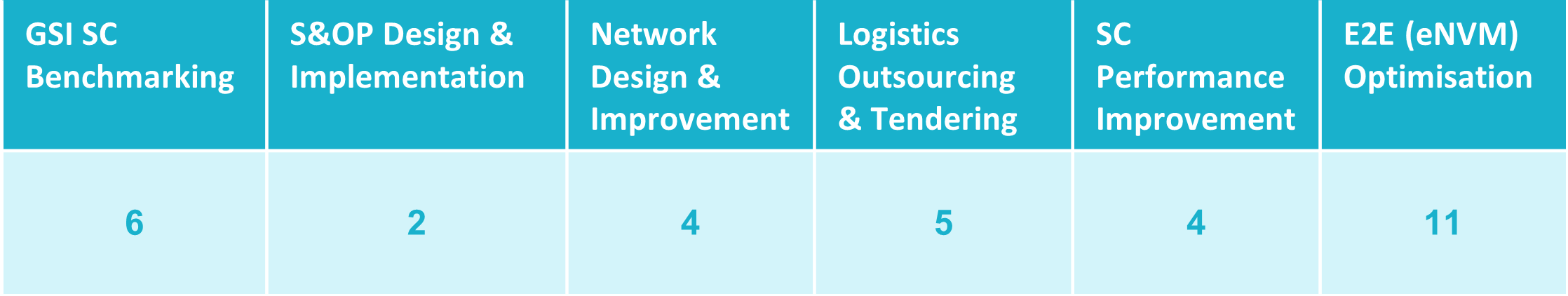

In addition to supporting our clients in the following projects to improve availability, reduce cost and lower environmental impact, our E2E optimisation and collaboration projects are demonstrating a resounding potential to reduce costs.

Highlights for 2023

- GSI transport benchmarking - >£100m spend evaluated

- Tendering and outsourcing - supported contracts worth >£200m

- 2 S&OP implementations realising significant improvements within 12 weeks

- E2E optimisation of supplier and retailer chains identifying £ms of saving

We have expanded our Supply Chain Best Practice membership to c.50 ambient and chilled suppliers and added more initiatives. Year on year we are seeing the level of engagement increase as a result of even more focused topics that aim to drive industry change. The best practice groups are endorsed by suppliers and retailers alike for being collaborative, innovative and results driven. We pride ourselves on being known for facilitating 'doing' groups, rather than just talk-shops.

Maintaining our award-winning supply chain excellence approach we remain keen to engage with new members who are willing to invest in challenging the status quo to help make a difference for the sector.

Good Faith Receiving

GFR continues to see great progress and currently stands at a 95% reduction in claims against the original 2014 results.

We continue to help our members best engage with retailers and assess their logistics capability and claims processes against best in class.

GRNI & Product Differentiation Best Practice

Our GRNI subgroup support suppliers in recovering monies owed for non-payment of goods (delayed payment). Nearly £2m has been recovered from multiple retailers by 7 suppliers to date, and consequently new suppliers are joining the campaign in 2024.

Amazon

The most significant challenges for suppliers trading with Amazon remain the numerous price and quantity deductions and chargebacks, but by sharing best practice on reducing supplier errors and raising the Amazon issues with the GCA, we are beginning to make a real difference.

The most significant challenges for suppliers trading with Amazon remain the numerous price and quantity deductions and chargebacks, but by sharing best practice on reducing supplier errors and raising the Amazon issues with the GCA, we are beginning to make a real difference.

Amazon recently launched their Dispute Management dashboard and we are gathering supplier feedback on its ease of use and accuracy (mixed views thus far) to share with their Code Compliance officer. Read supporting article in The Grocer.

We are planning a fulfilment centre visit with Amazon and suppliers to improve the end-to-end understanding of both parties and reduce the numbers of erroneous debits and chargebacks.

This opportunity is available to members who are willing to share their feedback, so please email us to register interest.

Sales Forecasting & Promotions Management

Forecasting continues to be a top ranked issue reported by suppliers to the GCA.

In 2023 we focused on creating a best practice framework to help the GCA engage with those retailers who have the greatest opportunity to improve.

This year we are increasing our focus on supplier best-practice, engaging with retailers directly to improve the effectiveness of retailer and supplier collaboration and improve the quality of information shared, especially as new systems are introduced.

Launch of Decarbonising Logistics Workgroup

Facing into the increasingly urgent need to reduce our carbon footprint and with HGV’s accounting for c.20% of the UK’s transport carbon emissions, the logistics sector has a critical role in achieving net zero by 2050.

At our inaugural sustainability event held last November, over 30 suppliers aligned around the imperative to take practical steps now, rather than wait for a scalable technological solution. Many individual operators feel they have already got as far as they can on their own and recognise that increased collaboration is crucial for suppliers, logistics providers and retailers to accelerate efforts to increase their efficiency and reduce CO2 at the same time.

Working Smarter, Together

We have introduced the Decarbonising logistics Group for 2024, with feedback already confirming the benefit of two distinct work streams to target emissions:

- Road Haulage – optimising pallet and vehicle fill, reducing road miles and sharing best practice on the effective adoption of alternative fuels.

- Modal Shift to Rail - leveraging a growing network of rail-enabled terminals to convert more movements to rail.

![]()

2023 confirmed the potential of our end-to-end optimisation trials using our collaborative modelling framework. So far we have enabled suppliers and retailers to identify E2E opportunities to reduce cost and waste by 15-30%, as well as measure reductions in CO2 consumption and packaging at case level.

Several of our chilled members have already successfully participated in trials in ASDA, with results revealing significant efficiencies:

Results to Date

Order frequency reduced to 2x weekly for many skus

Order frequency reduced to 2x weekly for many skus- Order sizes tripled with case-picking reduced by >90% on most skus

- Handling costs fell for both retailers and suppliers, saving £100ks for both

- Perhaps most surprisingly, availability and sales grew, but wastage did not

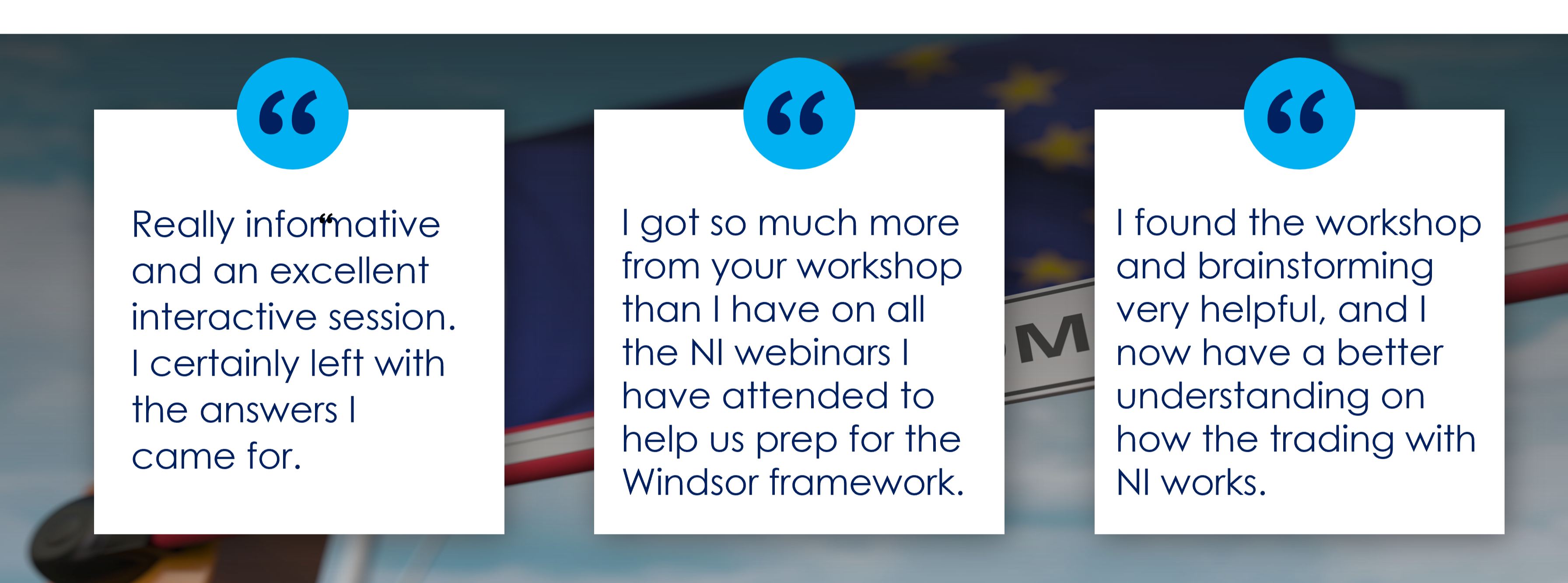

With new import controls being implemented from 2023 through into 2025, and with most suppliers scoring less than 5/10 in our pre-workshop quiz, it was clear navigating the complexity of labelling, GB imports and exports remains a challenge.

We received fantastic feedback on our Customs and Borders workshops, sharing insight into the implications of the Windsor Framework, labelling, GB imports, GB exports and changes to the wider BTOM, thanks to some invaluable input from Defra and Rob Hardy, CEO of EORI.

If you would like support on your customs and borders solution, contact EORI sales@eori.uk for expert advice.

The Next Driver Shortage

With Driver Require & Kieran Smith

In 2023 we continued to engage Kieran Smith of Driver Require via our workgroup meetings, reporting on the driver shortage in the industry.

Despite operating at a ‘chronic low-level shortage’ level for many years, which led to the shortage in 2022, we still have far too few younger drivers to replace those set to retire...so how do we plan to avoid another crisis in the coming years?

![]() For a comprehensive summary of the current situation, click to read, 'The HGV driver shortages: how can another crisis be avoided' where Jonathan was interviewed.

For a comprehensive summary of the current situation, click to read, 'The HGV driver shortages: how can another crisis be avoided' where Jonathan was interviewed.

Transport Benchmarking: Are You Getting the Best Value Out of your Distribution

As logistics costs continue to rise, knowing you are getting the best value for money is more important than ever. Benchmarking is a vital tool within logistics, but it can be hard to provide an apples-with-apples comparison for transport operations, especially when considering whether to tender, renew or outsource your solution.

Our Gold Standard Index (GSI™) transport benchmarking helps to quickly identify the areas of potential saving to tackle, without the need to run a tender, saving millions for suppliers to date.

By comparing your unique activity profile against the Gold Standard, we can compare you anonymously with your peers and other 3PL solutions, without breaching confidentiality.

A way to ensure you are getting value for your money.

A way to ensure you are getting value for your money.- Test the opportunity for savings without committing to a tender.

- Enabling an open discussion with providers to ensure a truly competitive service.

Transport Benchmarking

Market leading packaged goods manufacturer and a leading dairy manufacturer each needed an assessment of own fleet transport cost-effectiveness as well as that of their subcontractors.

Both clients reduced their core fleet as a result of the project, revising their planning team’s approach to sub-contraction and own fleet to provide an immediate boost in cost-effectiveness.

Proud to partner with